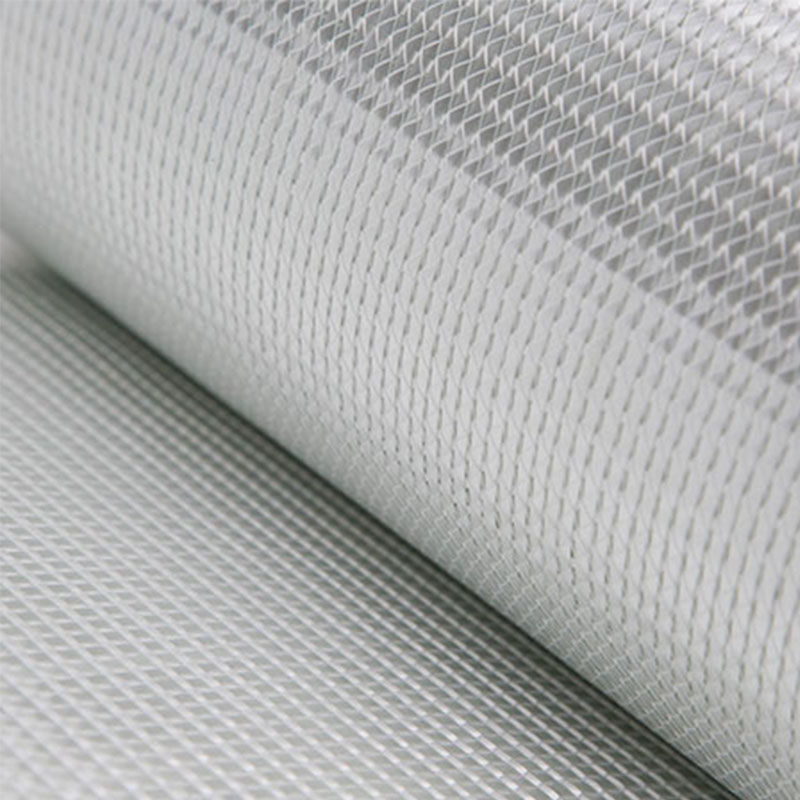

Advantages: Lightweight and Durable: Resin-based roofing tiles are significantly lighter than traditional materials like clay or concrete, reducing the load on the roof structure and making them easier to transport and install. They also exhibit excellent durability, withstanding harsh weather conditions, UV radiation, and impact.

Application scenarios: Commercial Roofing: Resin roofing tiles are also gaining popularity in commercial buildings due to their durability, low maintenance, and energy efficiency. They are suitable for office buildings, retail stores, and industrial facilities.

Technical index of liquid resin (25℃):

| Item | Unit | Index | Testing method |

| Appearance | --- | light yellow transparent liquid | GB/T8237.6.1.1-2005 |

| Hazen | --- | ≤60 | B 42300 |

| Viscosity | Pa·s | 0.15~0.25 | GB/T 7193.4.1-2008 |

| Gel time | min. | 16.0~26.0 | GB/T 7193.4.6-2008 |

| Non-volatile material | --- | (64.0~70.0)% | B 22301 |

Note: Gel time measurement: RCA 2.0%, curing agent Butanox M50 2.0%.

Instructions:

RC-C-1060 100 units

Curing agent Butanox M-50 2 units

Colorless accelerator 0.5~2 units (the amount depends on the temperature)

Physical properties of casting body (for reference only)

| Item | Unit | Factual Value | Testing Method |

| Tensile Strength | MPa | 50 | GB/T2567-2008 |

| Elongation at Break | --- | 3.0% | GB/T2567-2008 |

| Bending Strength | MPa | 95 | GB/T2567-2008 |

| Heat

Distortion

Temperature | ºC | 64 | GB/T1634-2004 |

| Oxygen Index | --- | 28% | GB/T2408-2008 |

Note:

1) The manufacturing method of the pouring body: according to GB/T8237-2005, the thickness of the oxygen index test piece is 3mm; the curing system: curing agent MEKP (Huangyan) 2.0%, colorless accelerator E5 1.0%;

2) Post-treatment of the pouring body: room temperature × 24 hours + 60°C × 3 hours + 80°C × 1 hour.

Notices:

The product should be stored in a cool place below 25ºC, avoid fire, and keep away from heat and radiation sources. The shelf life of storage below 25ºC is 3 months after leaving the factory.

yomi@rulecomposite.com

yomi@rulecomposite.com